Center for control and examination (CCCE)

Porečka 5, Belgrade

Founded in 2005

Activity: Non-Destructive Testing of Metals (NDT)

Since the establishment of our company, the largest share of business is related to hydroelectric plants. During these activities we put emphasis on the development of rehabilitation technologies, as well as on the inspection and testing of turbine and hydromechanical equipment at hydroelectric facilities.We note that each year we carry out tests on over 30 runner, all three species (Kaplan, Francis and Pelton), as well as to repair the damage caused by cavitation and cracks on the site without expensive equipment removal.The rehabilitation is carried out by trained and qualified personnel with savvy appliances and additional material, adapted for operation in technically difficult conditions.

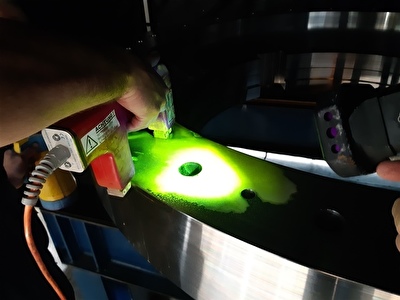

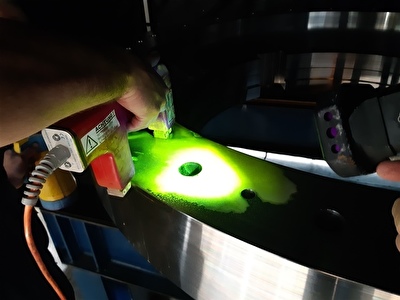

MT examination

Magnetic particle inspection (MT) is a non destructive test (NDT) method used to check for surface and near-surface discontinuities in ferrous materials. Our magnetic particle testing is performed on-site or in one of our state-of-the-art laboratories. Because this method relies on a magnetic field to produce results, it works best on ferrous materials, like nickel, iron, cobalt, and some alloys. Components like billets, bars, castings, forgings, fasteners, weldments and extrusions are also commonly tested using magnetic particle inspection.

PT examination

Liquid penetrant inspection (PT), or dye penetrant inspection, is a reliable, efficient, and cost-effective method for detecting surface flaws of welds, castings, and other components that cannot be destroyed. PT is a portable surface inspection method, allowing our Engaged Experts to conduct comprehensive onsite penetrant inspection.

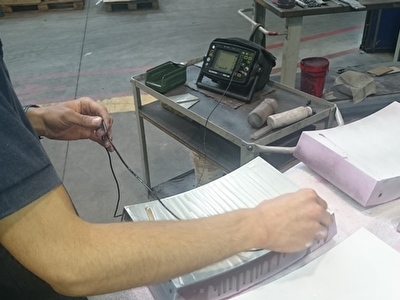

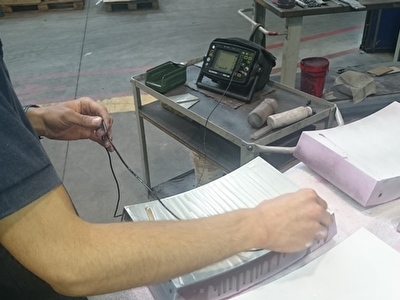

UT examination

Ultrasonic testing (UT) is a non-destructive test method that utilizes sound waves to detect cracks and defects in parts and materials. It can also be used to determine a material’s thickness, such as measuring the wall thickness of a pipe. Because this method has higher power potential than other non-destructive test types, ultrasonic testing can produce images that are more clearly defined than other methods and indicate characteristics deeper than surface level.

Activity

Activity:

Testing of metals by methods without destruction of NDT; Receiving and controlling equipment for hydro power plants; Development of technical conditions for the delivery of turbine and hydromechanical equipment; Rehabilitation of cracks, as well as zones damaged by cavitation on all three types of runner.(Kaplan, Pelton and Francis); Preparation of test reports in accordance with current valid standards in this field (IEC, CCH70, EN).

Equipment

Equipment:

Contemporary test equipment in accordance with applicable standards in this field;

Ultrasonic device USM32XL- Generalelectric; Ultrasonic device USM36- Generalelectric;

Magnetic particle tester with UV lamp - 3 sets; Penetrant staining agents;

Surface roughness measuring device;

Device for thickness measurement paint;

Measuring device; Auxiliary tool and means for visual and dimensional control.

Certificates

Certificates:

ISO 9001/2015 quality system;

Certificates for VT, MT, PT, and UT Level 2 methods;

Certificates IWE;

Welders atest REL, MIG, MAG

Reference list

Reference list:

Testing and repair work on turbine and hydromechanical equipment, as follows:

HPP Djerdap 1 - Serbia;

RHPP and HPP Bajina Basta - Serbia;

HPP Zvornik - Serbia;

Limske HPP - Serbia;

HPP Pirot - Serbia;

Vlasinske HPP - Serbia;

HPP Elektromorava - Serbia;

HPP Visegrad - Bosnia and hercegovina;

HPP Trebinje - Bosnia and hercegovina;

HPP Bočac - Bosnia and hercegovina;

HPP Jajce1 - Bosnia and hercegovina;

RHPP Čapljina - Bosnia and hercegovina;

HPP Perućica - Montenegro;

HPP Piva - Montenegro;

HPP Donje - Švedska

HPP Linnvasselv - Švedska

Reception and interphase control of new equipment during revitalization:

Reception and interphase control of new equipment during revitalization:

HPP Perućica - Montenegro;

HPP Elektromorava - Serbia;

HPP Bajina Bašta - Serbia;

HPP Zvornik - Serbia;

These are just some of the tasks related to the hydropower sector, for all the above, it is possible to provide evidence in the form of certificates from the contracting authority on the performed business as well as the contracts for which the jobs have been completed.

Cooperation with European companies from hydro energy efficiency:

VOITH HYDRO,

ANDRITZ,

ANDINO,

LMZ,

FICHNER,

RITTMAYER…

Jobs at NDT testing of generator and turbine equipment:

Jobs at NDT testing of generator equipment:

Steel structures and welded joints of stator frame

Steel structures of the rotor spider

Steel constructions of the upper and lower brucket of the generator.

Edge and general adhesion of the leading and bearing segments

Generator shaft (transient radius and shaft body)

Jobs at NDT testing of turbine equipment:

Turbine shaft (transient radius and shaft body)

Steel construction and welded joints of turbine coverBlades of a wicket gates and wicket gate levers

Blades of the runnerEdge and general adhesion of the leading and bearing segments

Bottom ring steel structure

Steel construction of Thrust ring and sealing ring.

Steel construction of druft tube cone